TMJ can eliminate waste with systems such as Magi Cut and our environmentally controlled timber storage facility contributes to waste reduction. On average, less than 10% of sheet material processed through the wood store is wasted and the system can determine whether an offcut is suitable for re-use, thereby supporting both prevention and re-use. Staff are also encouraged to recycle whenever possible, and any wood waste is used for power generation either on or off site. At our local energy plant, general waste is also used to generate energy. Unwanted samples are sent to local schools and colleges so that students can use them for their own coursework. We recently committed to a closed loop system for its protective material, correx. The correx is manufactured by a company that works with waste contractors on construction sites to collect and separate waste, and the correx is removed and returned to the original manufacturing facility to be recycled into more correx.

TMJ Interiors follows the waste hierarchy of Prevention, Reuse, Recycling, Recovery, and Disposal

Latest News

We’re delighted to announce Josh Day has joined...

Our first year apprentices faced a timed challenge...

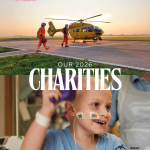

We are excited to be supporting East Anglian...

Starting the year off strong with refreshed machinery...

Team TMJ proudly rocked their Christmas jumpers today...

From the moment Luke Newton started his apprenticeship...